We carried out a turnkey project for this client, from study through completion.

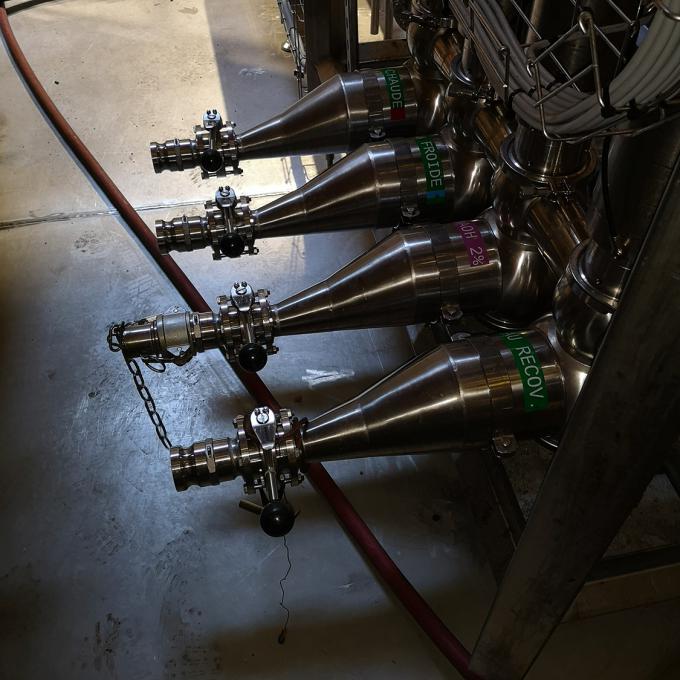

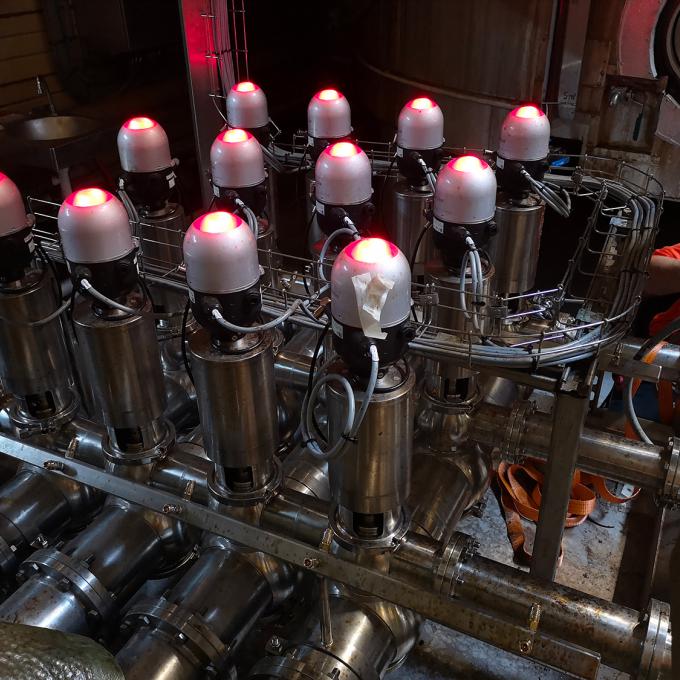

To create this new production line, we carried out a 3D study for the project, developed the new design and specifications and selected the most appropriate materials. INOVEX produced the tanks and installed the connectors (process and energy) for steam, cleaning in place (CIP) and compressed air.

This installation relies on more than two kilometres of pipeworks. While the project involved four months of development, it was commissioned in one week. The CIP (cleaning in place) station improves the ability to clean the factory’s pipeworks. The pipeworks were pre-manufactured in our workshops before being installed.

Deployment

September 2019 / October 2019

Business sectors

Agri-food

Location

Liège